Rub Resistance Tester

Product Details:

- Features Programmable, automatic stop, includes counter

- Power Supply AC 220V, 50 Hz

- Display Type LCD digital display

- Application Used for determining the rub resistance of printed materials, inks, labels, packaging, and coatings

- Port Size 6 mm quick connect

- Response Time Instantaneous digital reading

- Operating Voltage 220V AC

- Click to View more

Rub Resistance Tester Price And Quantity

- 1 Piece

Rub Resistance Tester Product Specifications

- 140 x 30 mm (standard specimen)

- 1 cycle

- AC 220V, 50 Hz

- Programmable, automatic stop, includes counter

- Approx. 36 kg

- LCD digital display

- 50 Hz

- 60 mm

- 1 cycle

- Instantaneous digital reading

- 100 mm (sample thickness limit)

- 6 mm quick connect

- Used for determining the rub resistance of printed materials, inks, labels, packaging, and coatings

- 60 mm

- 0.4 ~ 0.7 MPa

- Laboratory/Industrial

- 2 positions (simultaneous test)

- Digital control panel

- 220V AC

- 43 cycles/min (standard), adjustable

Rub Resistance Tester Trade Information

- Mumbai

- Cash Advance (CA)

- as per the buyers requirement Per Week

- 1 Minutes

- Depends on the machine.

- North America, Eastern Europe, Middle East, Africa, Central America, Australia, South America, Western Europe, Asia

- All India

- ISO-9000:2015

Product Description

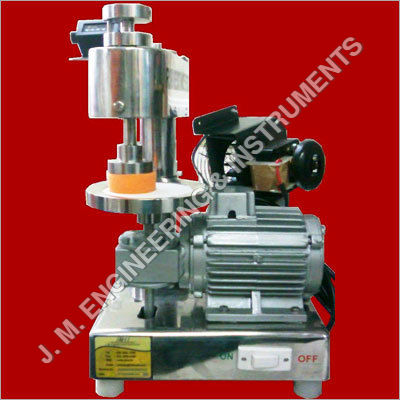

Backed by a diligent team of professionals, we are engaged in offering a quality range of Rub Resistance Tester. The offered lab testing equipment is designed and fabricated by our skilled professionals using exceptional quality components in line with the defined industry norms, and is ideal for use in testing ink/print, marking and rubs resistance of cartons, films and commercial printed material. Clients can avail this Rub Resistance Tester at competitive prices.

Features:

-

Robust construction

-

Reliability

-

Low maintenance

-

Accuracy in measurement

-

Longer life

Features:

-

Robust construction

-

Reliability

-

Low maintenance

-

Accuracy in measurement

-

Longer life

Applications:

- Rub Resistance Tester is used in ink rub test of ink layer on materials like labels, folding cartons, corrugated boxes etc.

- This equipment is designed to increase the efficiency, repeatability and safety of rub proof testing.

- The instrument is used for testing the ink/print, marking and rubs resistance of cartons, films and commercial printed material.

- It is available in three models Standard, Digital & Deluxe.

Precision Testing for Printed Materials

This Rub Resistance Tester ensures accurate assessment of abrasion resistance in a variety of printed substrates, from labels to packaging. Its advanced digital controls and preset counter simplify laboratory workflows, guaranteeing repeatable, high-resolution test results. Operators benefit from instant digital readings and programmable automated operation, which minimizes manual intervention while maximizing consistency.

Durable Construction and User-Friendly Design

Engineered with high-quality anodized aluminum and stainless steel components, this tester offers longevity and stability during testing. The LCD digital display and digital control panel create an intuitive user interface, while adjustable test speed and specimen positioning support diverse sample requirements. Its quiet operation and compact footprint suit both laboratory benches and industrial production rooms.

FAQs of Rub Resistance Tester:

Q: How does the Rub Resistance Tester determine the abrasion resistance of printed materials?

A: The tester uses a preset electronic counter and a stainless steel test head to simulate repetitive rubbing cycles on the sample surface. Results are instantly displayed on the LCD panel, showing cycle counts with 1 cycle accuracy to assess how well the material withstands abrasion.Q: What types of specimens can be tested with this instrument?

A: This device accommodates standard specimens sized 140 x 30 mm, with a maximum sample thickness of 100 mm. It is suitable for printed materials, inks, labels, packaging, and coatings to evaluate their rub resistance properties.Q: When is rub resistance testing important in manufacturing and packaging?

A: Rub resistance testing is essential when quality assurance for printed goods is required, such as before the release of product packaging, shipping labels, or marketing materials. It ensures durability and legibility under physical handling and environmental stress.Q: Where is this tester commonly used?

A: The tester is widely employed by laboratories and industrial facilities engaged in printing, packaging, and coating production. It is ideal for exporters, importers, manufacturers, suppliers, and traders across India who need reliable quality assessments.Q: What is the process for conducting a test?

A: Samples are secured in the anodized aluminum holder, test settings are entered via the digital control panel, and the test begins at the programmed speed. The instrument automatically rubs the specimens, counts each cycle electronically, and stops once the preset cycle count is achieved.Q: How does the programmable automatic stop feature benefit users?

A: The automatic stop function ensures that tests run precisely for the number of cycles required without operator intervention, which minimizes errors and enables more efficient test sequences in both research and industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Testing Equipments' category

|

J. M. ENGINEERING & INSTRUMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |