Standard Rub Resistance

Product Details:

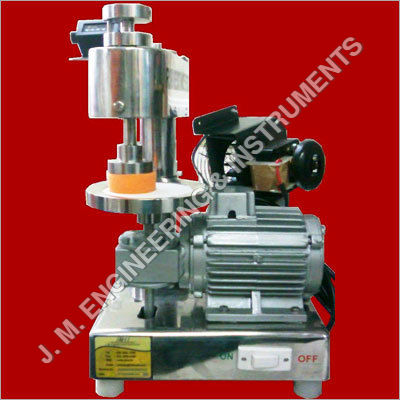

- Equipment Type Rub Resistance Tester

- Port Size 6 mm

- Power Supply AC 220 V, 50 Hz

- Interface Type Panel key interface

- Temperature 1540C

- Application Used to test the rub resistance and abrasion of printed materials

- Measuring Range User selectable

- Click to View more

X

Standard Rub Resistance Price And Quantity

- 1 Piece

Standard Rub Resistance Product Specifications

- Panel key interface

- 1540C

- Used to test the rub resistance and abrasion of printed materials

- Automatic stop, precise speed control, robust construction, adjustable pressure

- User selectable

- LCD Digital Display

- 50 Hz

- 1 cycle

- 0.40.7 MPa

- 45 kg

- 1 cycle

- 431 cycles/min

- 60 mm

- Rub Resistance Tester

- 6 mm

- AC 220 V, 50 Hz

- 50 mm (max)

- Industrial/Laboratory

- Digital preset counter with automatic stop

- 0999,999 cycles

- Up to 4 samples simultaneously

- 150 mm

- 35%85% RH

- 14

- 220 V

- 220 16 mm or 60 220 mm

- Immediate

Standard Rub Resistance Trade Information

- Mumbai

- Cash Advance (CA)

- as per the buyers requirement Per Week

- 1 Months

- Depends on the machine.

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- All India

- ISO-9000:2015

Product Description

Standard Rubresistance

- Rub Resistance Tester is used in ink rub test of ink layer on materials like labels, folding cartons, corrugated boxes etc.

- This equipment is designed to increase the efficiency, repeatability and safety of rub proof testing.

- The instrument is used for testing the ink/print, marking and rubs resistance of cartons, films and commercial printed material.

- It is available in three models Standard, Digital & Deluxe.

Versatile and Accurate Testing

Designed for rigorous material testing, this rub resistance tester suits a wide measuring range with user-selectable settings. Its immediate response time and LCD digital display offer clear, precise data. Supporting specimen sizes up to 220 16 mm or 60 220 mm, and simultaneous testing of up to four samples, it optimizes productivity and ensures uniform, repeatable results for research, manufacturing, and quality control needs.

Safety and Durability Focused

Safety is paramount in this equipment, featuring overload protection and an emergency stop button for immediate intervention. The powder-coated finish resists wear and corrosion, while the robust construction assures a long operational lifespan. Designed for reliability in diverse industrial or laboratory conditions, its quiet operation and ergonomic controls enhance user experience and workplace safety.

FAQs of Standard Rub Resistance:

Q: How does the Standard Rub Resistance Tester operate?

A: The tester uses precision ground stainless steel as the contact surface to rub specimens, simulating real-world abrasion. With digital preset controls, you can select the exact number of cycles and pressure, and the machine automatically stops when the test ends. Its LCD display shows ongoing test parameters in real-time.Q: What materials and specimen sizes can the tester handle?

A: This tester is suitable for a variety of printed materials, supporting specimen sizes of 220 16 mm or 60 220 mm. It can evaluate up to four samples at once, accommodating both single and multiple testing requirements for industrial or laboratory settings.Q: When should I use the rub resistance tester?

A: The tester is ideal for assessing the durability of printed materials prior to product release, during research and development, or as part of routine quality assurance in manufacturing facilities. Use it whenever verifying rub resistance or material longevity is critical.Q: Where can this equipment be utilized?

A: This instrument is commonly used in industrial production lines, research laboratories, and quality control departments, particularly in printing, packaging, and related material manufacturing sectors, throughout India and internationally.Q: What is the process for conducting a rub resistance test?

A: Simply place the specimen into the holder, set the desired cycle count and pressure using the panel key interface, and initiate the test. The system runs at a speed of 431 cycles/min over a 60 mm stroke, automatically stopping upon reaching the preset value. Results are instantly displayed for analysis.Q: How does the tester ensure user safety?

A: Equipped with overload protection and an emergency stop button, the tester provides immediate shutdown capability in case of mechanical or electrical fault, ensuring operator safety during all testing operations.Q: What are the benefits of using this rub resistance tester?

A: Users benefit from its precise speed control, adjustable pressure, robust build quality, and quiet operation (<60 dB). Its automatic stop feature, immediate test data, and capacity for multiple samples improve efficiency and accuracy, supporting stringent quality control and research requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Testing Equipments' category

|

J. M. ENGINEERING & INSTRUMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |