Deluxe Bursting Strength Tester

Product Details:

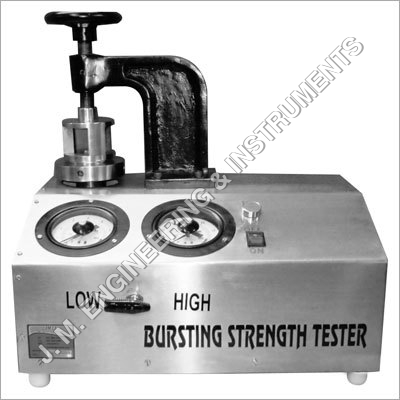

- Features Heavy base, robust construction, manual hand wheel, safety shield, stable operation

- Application Paper, Board, Cardboard, Corrugated Fiber Board, Textile, Leather, Foil, Sheets

- Gas Pressure Not required (hydraulic mechanism)

- Port Size Standard as per test method

- Frequency 50 Hz

- Equipment Type Bursting Strength Tester

- Humidity 20% to 85% RH

- Click to View more

X

Deluxe Bursting Strength Tester Price And Quantity

- 1 Piece

Deluxe Bursting Strength Tester Product Specifications

- LCD Display / Dial Gauge

- Bench/ Floor Mounted

- 30.5 mm (standard as per IS 1060)

- 20% to 85% RH

- 50 Hz

- Bursting Strength Tester

- Not required (hydraulic mechanism)

- Standard as per test method

- Paper, Board, Cardboard, Corrugated Fiber Board, Textile, Leather, Foil, Sheets

- Heavy base, robust construction, manual hand wheel, safety shield, stable operation

- Laboratory, Quality Control

- 230V AC 10%, 50 Hz

- 220 V AC, 50 Hz

- 10C to 40C

- Instantaneous

- Manual/Automatic

- 0.1 kg/cm

- 95 5 mm/min

- Independent specimen mount

- approximately 60 kg

- 1% of reading

- 1 per test

- 550 mm

Deluxe Bursting Strength Tester Trade Information

- Mumbai

- Cash Advance (CA)

- as per the buyers requirement Per Week

- 1 Months

- Depends on the machine.

- Australia, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia, North America

- All India

- ISO-9000:2015

Product Description

Bursting Strength Tester Deluxe Model

By keeping track with the current market developments, we are engaged in offering Bursting Strength Tester. This product is widely appreciated for its accurate functionality, sturdy design, corrosion resistance, reliability and high durability. We have fabricated this range using quality tested raw materials and advanced machinery under the guidance of skilled professionals. This product is widely used to find the bursting strength of fabric, leather, paper, paper board and aluminium foil. We offer this Bursting Strength Tester in various specifications at the most competitive prices.

Precise and Versatile Testing

Engineered for accuracy, the Deluxe Bursting Strength Tester accommodates a wide array of substrates including paper, board, fabric, leather, and foil. With adjustable clamping and instant response time, this machine ensures reproducible results for critical quality assessments. Both manual and automatic control modes provide flexibility during operation.

User-Friendly and Safe Operation

This tester is equipped with overload protection and a transparent shield for enhanced operator safety. The wooden case packaging, powder-coated finish, and heavy base contribute to durability and operational stability, while an intuitive LCD or dial gauge affords easy result reading. Suitable for laboratories and industrial quality control setups.

Designed for High Standards

Made as per IS 1060 and relevant test standards, this tester features a hydraulic mechanism using castor oil or approved equivalents, negating the need for gas pressure. Its interface options and adjustable features allow seamless integration with various quality control workflows, ensuring compliance and reliability.

FAQs of Deluxe Bursting Strength Tester:

Q: How is a test conducted using the Deluxe Bursting Strength Tester?

A: To conduct a test, mount a specimen ( 30.5 mm as per IS 1060) onto the independent specimen holder, set the required clamping pressure, and select manual or automatic mode. The hydraulic system will increment pressure via castor oil, and the bursting strength will be recorded when the sample fails. Results are displayed on the LCD or dial gauge.Q: What materials and thicknesses can this tester accommodate?

A: The tester is suitable for paper, board, cardboard, corrugated fiber board, textile, leather, and foil sheets. It is optimized for standard specimen sizes as per IS 1060, making it ideal for a broad range of laboratory and quality control applications.Q: Where should the Deluxe Bursting Strength Tester be installed and used?

A: The tester is best installed in laboratory or quality control environments with temperature control between 10C40C and relative humidity of 20%85%. Its bench or floor mounting design ensures stable and safe operation in these settings.Q: What process does the hydraulic mechanism use, and what fluid is required?

A: The tester utilizes a hydraulic mechanism powered by castor oil or an approved equivalent. No gas supply is needed, and the hydraulic fluid enables precise and consistent pressure application for accurate bursting strength measurements.Q: When should the machines overload protection feature be engaged?

A: The overload protection activates automatically if excessive force is detected during a test, safeguarding both the specimen and the tester from potential damage. This feature ensures tester longevity and operator safety during every cycle.Q: What are the main benefits of using this instrument for quality control?

A: The tester delivers high-precision results (1% accuracy) with instantaneous response, helping manufacturers ensure product integrity. Its robust construction, safety features, and standardized operation streamline quality checks and regulatory compliance, enhancing reliability in production processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Testing Equipments' category

|

J. M. ENGINEERING & INSTRUMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |