Cobb Tester

Product Details:

- Accuracy 1 gsm

- Display Type Graduated scale (manual reading)

- Response Time Test duration: typically 60, 120, 180, or 300 seconds

- Hardness Rubber mat provided as per standard

- Measuring Range Up to 200 gsm (grams per square meter)

- Max Height Approx. 160 mm

- Temperature 23C 1C (for standard tests)

- Click to View more

X

Cobb Tester Price And Quantity

- 1 Piece

Cobb Tester Product Specifications

- Rugged construction, easy clamping, stainless steel cylinder

- Diameter 112.8 mm (standard ring for 100 cm area)

- Bench Top

- Manual

- 0 200 gsm

- 23C 1C (for standard tests)

- Manual (Operator controlled)

- 1 per test

- Approx. 160 mm

- Manual

- Determining the water absorbency of paper, board, and corrugated fibreboard

- Rubber mat provided as per standard

- Up to 200 gsm (grams per square meter)

- Graduated scale (manual reading)

- Test duration: typically 60, 120, 180, or 300 seconds

- 1 gsm

- Testing as per standard environmental conditions (RH 65% recommended)

- 100 mm (standard for specimen ring)

- 100 ml graduated cylinder (for water uptake)

- 1 gsm

- Laboratory Testing

Cobb Tester Trade Information

- Mumbai

- Cash Advance (CA)

- as per the buyers requirement Per Week

- 1 Minutes

- Depends on the machine.

- Australia, North America, Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia

- All India

- ISO-9000:2015

Product Description

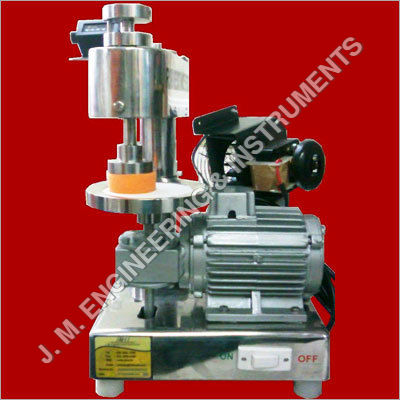

Cobb Tester

We are instrumental in providing our clients a comprehensive range of Cobb Tester. This range is globally appreciated for its sturdy construction, reliability, corrosion resistance, accurate measurements and high durability. The offered product is used to determine the water absorption property of paper, paper board and corrugated fiberboard. This range is designed and manufactured at our sophisticated manufacturing unit using high quality components and latest machinery. Clients can avail this Cobb Tester in various capacities at reasonable prices.

Versatile and Reliable Construction

Built with a stainless steel cylinder and a powder-coated base, the Cobb Tester ensures durability and resistance to corrosion, even under frequent laboratory use. The easy clamping system with a locking lever handle guarantees safe and secure specimen sealing, enabling reproducible testing every time. Its rugged design makes it an ideal choice for demanding pulp and paper laboratory environments.

Precision and Compliance

This device supports testing as per globally recognized standards such as IS 1060, TAPPI T441, and ISO 535. With a graduated scale for manual readings and a measuring range up to 200 gsm, the Cobb Tester provides accuracy within 1 gsm, giving dependable results. It includes user-friendly accessories that streamline the water absorbency testing process for papers and boards.

User-Friendly Operation and Safety

The Cobb Tester is manual, requiring operator control, and it offers a stable, bench-top mounting type. Designed with rounded edges for enhanced safety, the device minimizes risk during routine handling. Standard accessories and an instruction manual simplify setup and operation, making it suitable for laboratories and testing facilities of all sizes.

FAQs of Cobb Tester:

Q: How is the Cobb Tester used to evaluate water absorbency in paper and board?

A: The Cobb Tester measures water absorbency by exposing a standard-sized paper or board specimen (112.8 mm diameter, 100 cm area) to 100 ml of test liquid for a specified duration, typically 60 to 300 seconds. After the set time, the absorbed water is measured to determine the materials absorbency in gsm.Q: What materials are compatible with this Cobb Tester model?

A: This tester is ideal for paper, board, and corrugated fibreboard, offering accurate results for materials within a measuring range of 0 200 gsm, as per industry testing standards.Q: When should humidity and temperature be controlled during testing?

A: Maintaining standard environmental conditions23C 1C and 65% relative humidityis recommended for precise testing, in accordance with ISO and TAPPI guidelines. This ensures consistency and accuracy in absorbency results.Q: Where is the Cobb Tester typically installed and used?

A: The tester is designed for bench-top mounting in laboratory environments, such as quality control departments in manufacturing facilities or dedicated testing laboratories.Q: What is the procedure for conducting a test with this device?

A: Place the specimen on the rubber pad inside the stainless steel cylinder, lock the lever to seal, pour 100 ml of water onto the specimen, allow it to absorb for the chosen duration, drain the excess liquid, then measure and record the weight gain using the provided graduated cylinder and manual scale.Q: How does the locking lever mechanism improve testing?

A: The locking lever handle ensures secure sealing of the specimen within the test cylinder. This prevents leakage or shifting during the test, contributing to more reliable and reproducible results.Q: What are the primary benefits of using this Cobb Tester in laboratory testing?

A: This device offers accurate, reproducible water absorbency measurements, robustness through stainless steel construction, user safety features, compliance with international standards, and an easy manual operation, making it invaluable for quality assurance in the pulp and paper industry.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Testing Equipments' category

|

J. M. ENGINEERING & INSTRUMENTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |